SPOILER ALERT!

Tunnel Pasteurizers Are Machines That Are Made Use Of To Sanitize Packaged Items As Well As Expand Their Life Span

Created by-Mendoza Steffensen

These equipments include several areas that each include their very own water spray system and also blood circulation pump, along with a screen/filter box. When these systems malfunction, they can negatively affect the process, product top quality, performance, as well as overall price of ownership.

Tunnel Pasteurizers function by circulating hot water under the pasteurization belt. The water may be sent out to the discharge conveyor or to a sump. The sump is located under the pasteurization belt. As https://www.dairyfoods.com/articles/94770-conquer-contaminants-in-dairy-food-and-beverage-processing pass over the pasteurization belt, some of them might break. Damaged containers are accumulated in the sump. Otherwise, they proceed along the conveyor. The sump is designed to have water tight ports that allow maintenance employees accessibility to the water.

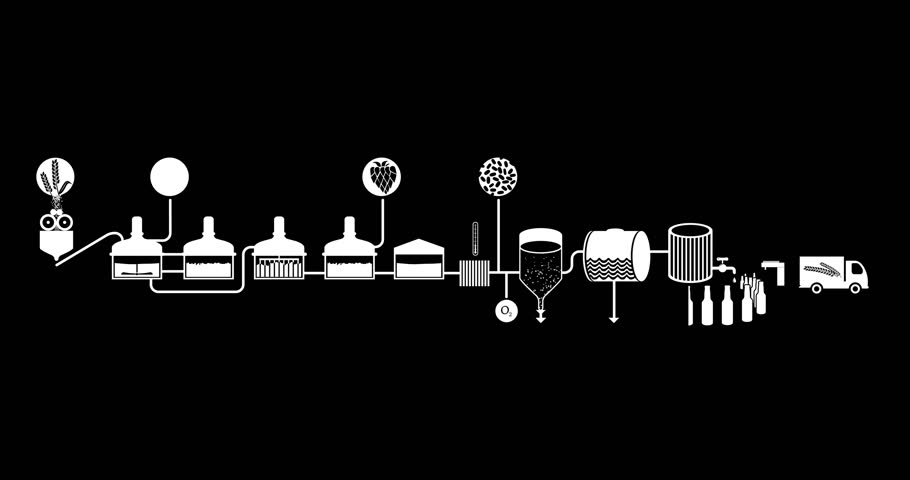

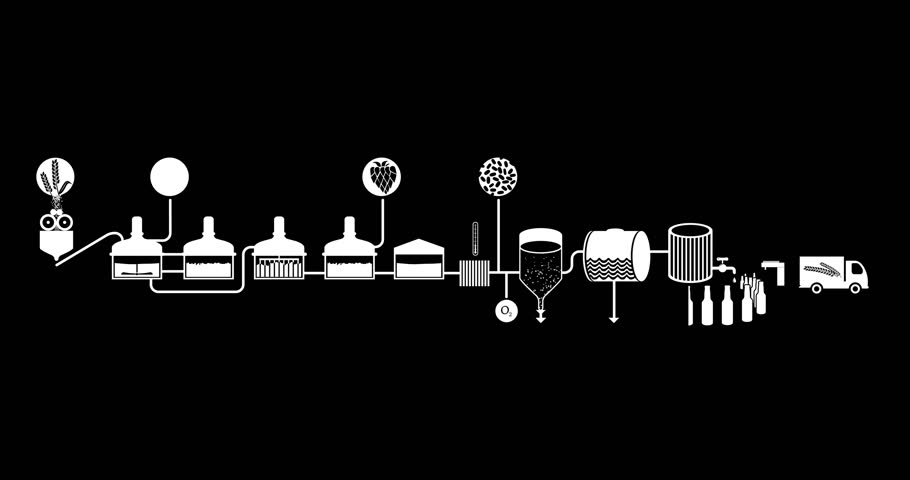

Tunnel Pasteurizers are perfect for a selection of applications. For example, Tunnel pasteurizers can be used for brewing beer, canned mixed drinks, as well as various other items that have a closed container. These gadgets can be customized to suit the production location of a company. They can be found in a range of dimensions, depending on the volume as well as temperature level needed for the items. If you require to deal with more than one item, you can set up a dual-story system.

Tunnel Pasteurizers can be an affordable means to decontaminate bottled beverages. They can likewise be highly energy efficient. They make use of advanced modern technology to eliminate microorganisms and enzymes that cause germs and also other unsafe substances. They additionally have a modular design for reduced installment expenses. Single-deck tunnels can vary from 5 to 500 m2. Constant belts are readily available in stainless steel and also polypropylene.

The Tunnel Pasteurizer can refine a wide variety of items, such as juices and jams. It can be geared up with an a/c system in the control closet. The temperature level and also time utilized during pasteurization differ according to the kind of product. A multitude of companies utilize these devices to pasteurize their items. They are likewise easy to maintain and service.

Tunnel Pasteurizers are reliable makers that eliminate germs, quit fermentation, and also give shelf stability to bottled products. These equipments are subjected to substantial temperature levels and caustic cleaning chemicals. They can additionally be damaged by busted containers. At PRO Engineering/Manufacturing, we have experience designing and also developing Tunnel pasteurizers for food and also drink companies.

Tunnel Pasteurizers are different from tubular, plate, and mass pasteurizers in a number of ways. The last has a recording device that tapes information of the procedure. This makes it an extra effective as well as exact way to warmth as well as awesome bundles. Tunnel Pasteurizers are commonly more affordable than bulk pasteurizers as well as are much more power reliable. Nevertheless, Recommended Looking at of the Tunnel pasteurizer can vary once in a while.

Depending on the water chemistry of the Tunnel pasteurizer system, containers and also cans can experience different top quality problems. For example, unlacquered containers and bottles can establish corrosion spots and discoloration. Unlacquered containers may also experience fading of decorations. Those who make use of these systems should examine their regional series of products.

Tunnel Pasteurizers can be an efficient way to decontaminate milk. This technology also permits manufacturers to prolong the life span of their products. Also small-scale breweries can gain from pasteurization. For example, if a brewery has no refrigeration tools, they can use Tunnel pasteurizers to disinfect their products. An effective industrial plant might have the ability to process up to 240,000 L of milk per hr.

These equipments include several areas that each include their very own water spray system and also blood circulation pump, along with a screen/filter box. When these systems malfunction, they can negatively affect the process, product top quality, performance, as well as overall price of ownership.

Tunnel Pasteurizers function by circulating hot water under the pasteurization belt. The water may be sent out to the discharge conveyor or to a sump. The sump is located under the pasteurization belt. As https://www.dairyfoods.com/articles/94770-conquer-contaminants-in-dairy-food-and-beverage-processing pass over the pasteurization belt, some of them might break. Damaged containers are accumulated in the sump. Otherwise, they proceed along the conveyor. The sump is designed to have water tight ports that allow maintenance employees accessibility to the water.

“WHAT IS THE BEST PASTEURIZATION METHOD FOR BEER AND BEVERAGES?”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) January 17, 2023

Article Release for Brewmasters & Beverage Makers, sponsored by PRO Engineering / Manufacturing Inc.

Click for full article:https://t.co/O633OluiN1

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/r2lM9FPwKp

Tunnel Pasteurizers are perfect for a selection of applications. For example, Tunnel pasteurizers can be used for brewing beer, canned mixed drinks, as well as various other items that have a closed container. These gadgets can be customized to suit the production location of a company. They can be found in a range of dimensions, depending on the volume as well as temperature level needed for the items. If you require to deal with more than one item, you can set up a dual-story system.

Tunnel Pasteurizers can be an affordable means to decontaminate bottled beverages. They can likewise be highly energy efficient. They make use of advanced modern technology to eliminate microorganisms and enzymes that cause germs and also other unsafe substances. They additionally have a modular design for reduced installment expenses. Single-deck tunnels can vary from 5 to 500 m2. Constant belts are readily available in stainless steel and also polypropylene.

The Tunnel Pasteurizer can refine a wide variety of items, such as juices and jams. It can be geared up with an a/c system in the control closet. The temperature level and also time utilized during pasteurization differ according to the kind of product. A multitude of companies utilize these devices to pasteurize their items. They are likewise easy to maintain and service.

Tunnel Pasteurizers are reliable makers that eliminate germs, quit fermentation, and also give shelf stability to bottled products. These equipments are subjected to substantial temperature levels and caustic cleaning chemicals. They can additionally be damaged by busted containers. At PRO Engineering/Manufacturing, we have experience designing and also developing Tunnel pasteurizers for food and also drink companies.

Tunnel Pasteurizers are different from tubular, plate, and mass pasteurizers in a number of ways. The last has a recording device that tapes information of the procedure. This makes it an extra effective as well as exact way to warmth as well as awesome bundles. Tunnel Pasteurizers are commonly more affordable than bulk pasteurizers as well as are much more power reliable. Nevertheless, Recommended Looking at of the Tunnel pasteurizer can vary once in a while.

Depending on the water chemistry of the Tunnel pasteurizer system, containers and also cans can experience different top quality problems. For example, unlacquered containers and bottles can establish corrosion spots and discoloration. Unlacquered containers may also experience fading of decorations. Those who make use of these systems should examine their regional series of products.

Tunnel Pasteurizers can be an efficient way to decontaminate milk. This technology also permits manufacturers to prolong the life span of their products. Also small-scale breweries can gain from pasteurization. For example, if a brewery has no refrigeration tools, they can use Tunnel pasteurizers to disinfect their products. An effective industrial plant might have the ability to process up to 240,000 L of milk per hr.