SPOILER ALERT!

Tunnel Pasteurizers Are Makers That Are Utilized To Decontaminate Packaged Products And Also Extend Their Life Span

Content author-Mendoza Charles

These devices contain numerous areas that each include their very own water spray system as well as circulation pump, in addition to a screen/filter box. When these systems malfunction, they can negatively influence the procedure, product high quality, performance, and complete expense of ownership.

Tunnel Pasteurizers function by distributing warm water under the pasteurization belt. https://www.sltrib.com/news/2019/11/15/utahs-first-breastmilk/ may be sent to the discharge conveyor or to a sump. The sump lies under the pasteurization belt. As containers overlook the pasteurization belt, a few of them might damage. Damaged containers are collected in the sump. Or else, they continue along the conveyor. The sump is designed to have water tight ports that enable maintenance employees accessibility to the water.

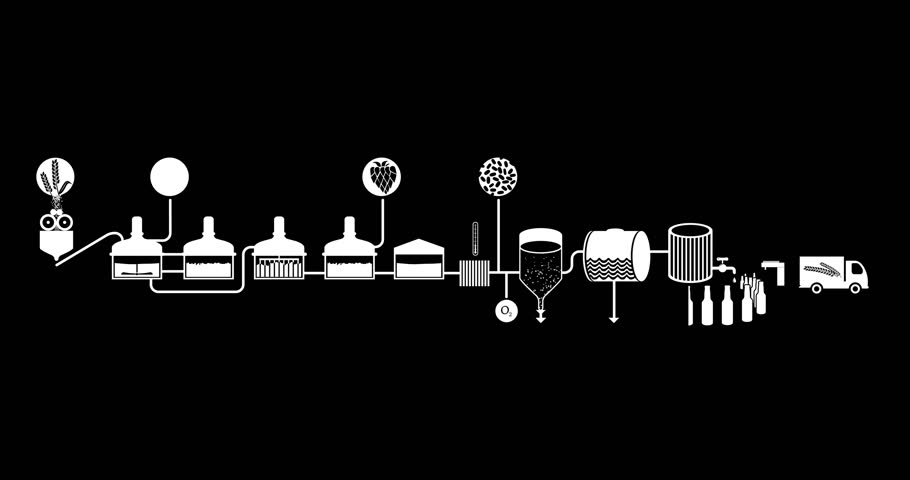

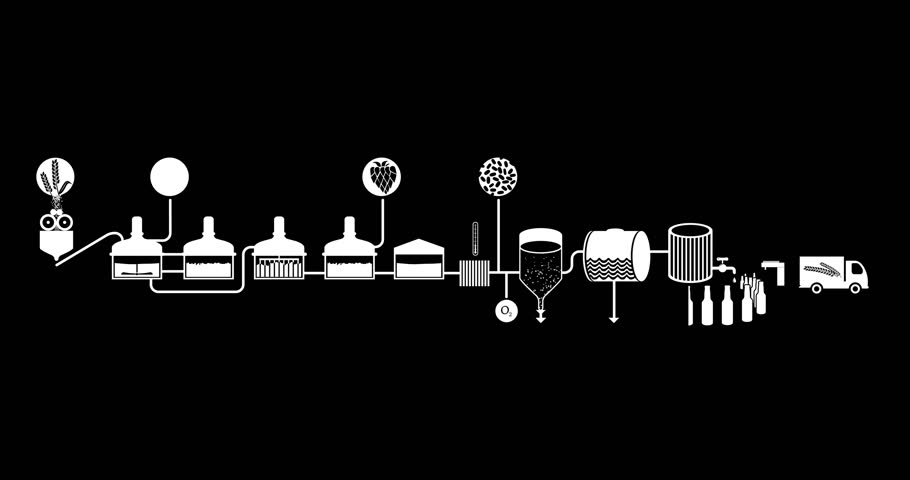

Tunnel Pasteurizers are optimal for a selection of applications. For example, Tunnel pasteurizers can be used for developing beer, tinned cocktails, and also various other items that have a closed container. These tools can be customized to fit the production location of a company. They come in a range of dimensions, relying on the quantity and temperature level needed for the products. If you need to treat more than one product, you can set up a dual-story device.

Tunnel Pasteurizers can be a cost-efficient method to sterilize bottled beverages. They can additionally be very energy reliable. They use innovative modern technology to kill microorganisms as well as enzymes that create germs and also other harmful materials. They likewise have a modular design for minimized installment expenses. Single-deck passages can range from five to 500 m2. Continual belts are offered in stainless-steel and also polypropylene.

The Tunnel Pasteurizer can refine a wide variety of products, such as juices and also jams. It can be furnished with a cooling system in the control cupboard. The temperature level and time utilized during pasteurization vary according to the type of item. A large number of companies utilize these tools to pasteurize their items. They are additionally very easy to preserve and also solution.

Tunnel Pasteurizers are efficient devices that eliminate microorganisms, quit fermentation, and provide rack security to bottled items. These makers are subjected to considerable temperature levels and caustic cleansing chemicals. They can likewise be harmed by damaged containers. At PRO Engineering/Manufacturing, we have experience making as well as building Tunnel pasteurizers for food as well as drink firms.

Tunnel Pasteurizers are different from tubular, plate, as well as mass pasteurizers in a number of means. The last has a recording gadget that tape-records information of the process. This makes it a more reliable as well as exact method to warm and trendy plans. Tunnel Pasteurizers are commonly less expensive than bulk pasteurizers as well as are much more power reliable. However, the temperature levels of the Tunnel pasteurizer can differ periodically.

Depending upon the water chemistry of the Tunnel pasteurizer system, containers and also containers can experience different top quality issues. For instance, unlacquered containers as well as bottles can develop corrosion spots as well as staining. Unlacquered cans may likewise experience fading of designs. Those who make use of these systems need to check their local variety of products.

Tunnel Pasteurizers can be an effective method to decontaminate milk. This technology additionally permits producers to lengthen the life span of their items. Also small-scale breweries can benefit from pasteurization. For example, if a brewery has no refrigeration tools, they can make use of Tunnel pasteurizers to decontaminate their items. A successful industrial plant might be able to refine up to 240,000 L of milk per hr.

These devices contain numerous areas that each include their very own water spray system as well as circulation pump, in addition to a screen/filter box. When these systems malfunction, they can negatively influence the procedure, product high quality, performance, and complete expense of ownership.

Tunnel Pasteurizers function by distributing warm water under the pasteurization belt. https://www.sltrib.com/news/2019/11/15/utahs-first-breastmilk/ may be sent to the discharge conveyor or to a sump. The sump lies under the pasteurization belt. As containers overlook the pasteurization belt, a few of them might damage. Damaged containers are collected in the sump. Or else, they continue along the conveyor. The sump is designed to have water tight ports that enable maintenance employees accessibility to the water.

Tunnel Pasteurizers are optimal for a selection of applications. For example, Tunnel pasteurizers can be used for developing beer, tinned cocktails, and also various other items that have a closed container. These tools can be customized to fit the production location of a company. They come in a range of dimensions, relying on the quantity and temperature level needed for the products. If you need to treat more than one product, you can set up a dual-story device.

Tunnel Pasteurizers can be a cost-efficient method to sterilize bottled beverages. They can additionally be very energy reliable. They use innovative modern technology to kill microorganisms as well as enzymes that create germs and also other harmful materials. They likewise have a modular design for minimized installment expenses. Single-deck passages can range from five to 500 m2. Continual belts are offered in stainless-steel and also polypropylene.

The Tunnel Pasteurizer can refine a wide variety of products, such as juices and also jams. It can be furnished with a cooling system in the control cupboard. The temperature level and time utilized during pasteurization vary according to the type of item. A large number of companies utilize these tools to pasteurize their items. They are additionally very easy to preserve and also solution.

Tunnel Pasteurizers are efficient devices that eliminate microorganisms, quit fermentation, and provide rack security to bottled items. These makers are subjected to considerable temperature levels and caustic cleansing chemicals. They can likewise be harmed by damaged containers. At PRO Engineering/Manufacturing, we have experience making as well as building Tunnel pasteurizers for food as well as drink firms.

Tunnel Pasteurizers are different from tubular, plate, as well as mass pasteurizers in a number of means. The last has a recording gadget that tape-records information of the process. This makes it a more reliable as well as exact method to warm and trendy plans. Tunnel Pasteurizers are commonly less expensive than bulk pasteurizers as well as are much more power reliable. However, the temperature levels of the Tunnel pasteurizer can differ periodically.

Depending upon the water chemistry of the Tunnel pasteurizer system, containers and also containers can experience different top quality issues. For instance, unlacquered containers as well as bottles can develop corrosion spots as well as staining. Unlacquered cans may likewise experience fading of designs. Those who make use of these systems need to check their local variety of products.

Tunnel Pasteurizers can be an effective method to decontaminate milk. This technology additionally permits producers to lengthen the life span of their items. Also small-scale breweries can benefit from pasteurization. For example, if a brewery has no refrigeration tools, they can make use of Tunnel pasteurizers to decontaminate their items. A successful industrial plant might be able to refine up to 240,000 L of milk per hr.