SPOILER ALERT!

Tunnel Pasteurizers For Procedures Like Ice As Well As Soft Drinks

Content written by-Horton Mccray

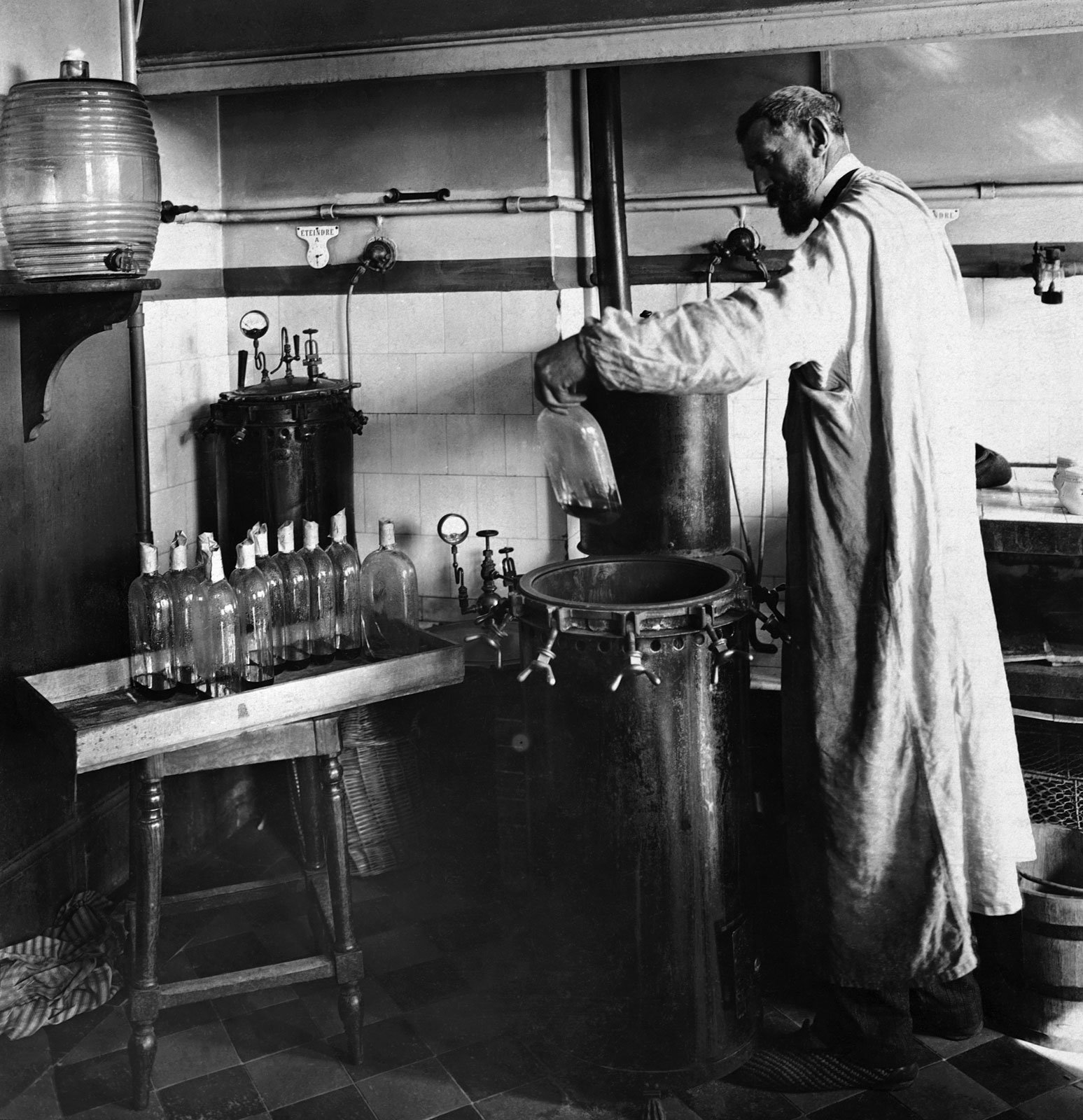

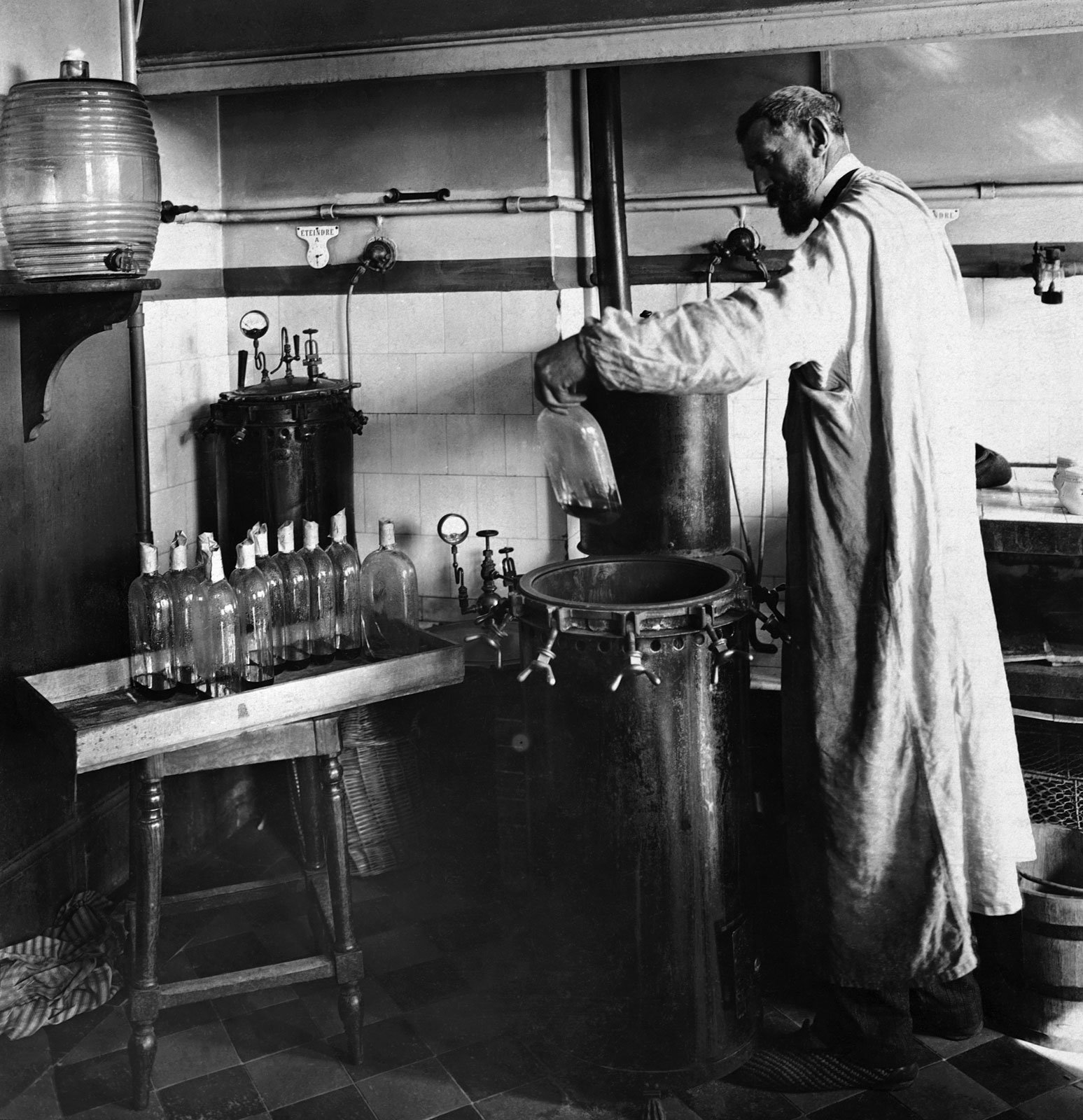

Batch pasteurizers are a popular type of sterilized food. This sort of pasteurizer is used to make refined food last much longer and also maintain it more delicious for a longer period of time. They are typically made use of in dining establishments and also fast food companies to expand the life span of prepared food as well as make it taste also better. There are 2 kinds of Tunnel pasteurizers readily available, set and bottle. Generally, food will be pasteurized at one cycle with a batch machine. Bottled pasteurizer systems are not made use of as frequently as the other type however they do still have their benefits.

Set Batch Pasteurizers are developed for large facilities or business that need to refine huge quantities of food per day. The process of making batch sterilized foods resembles the process made use of by internal warmth exchangers other than it has a heatpump rather than a warm exchanger. Set Tunnel pasteurizers have lots of advantages. They offer batch dimension control which allows you to change the amount of food that experiences the system based upon what you need. There are generally 5 cycles with the lengthiest being 2 hours.

"@context": "https://schema.org", "@type": "Organization", "name": "PRO Engineering / Manufacturing Inc", "url": "https://prowm.com/", "logo": "https://prowm.com/wp-content/uploads/2020/12/PRO_logo_NEW_BLK_large.jpg", "contactPoint": "@type": "ContactPoint", "telephone": "414-362-1500", "contactType": "customer service", "areaServed": ["US","PR"], "availableLanguage": "en" , "sameAs": [ "https://www.facebook.com/PartnerWithPRO", "https://twitter.com/daveone1", "https://www.youtube.com/channel/UCizF9v7dVwMEfY1Qu_E4MPg", "https://www.linkedin.com/company/pro-engineering-and-mfg-inc/", "https://soundcloud.com/pro-engineering-milwaukee" ]

Inner Warmth Exchangers are created for restaurants and also food handling plants to accomplish pasteurization of difficult core items like icy fish, hen, and sodas. The system uses tanks of heated water, in addition to a special detergent, to attain pasteurization. An internal warm exchanger will generally have a holding tank as well as a soft water storage tank to keep the proper water temperature. Some devices use both warm exchangers. To get the right temperature level, many makers make use of either electric pumps or gas-based heating units.

Bottled Batch Pasteurizers makes use of a process called carbonation. Carbonation is accomplished by subjecting the drink to high pressure air which compels co2 right into the interior of the bottle where the wanted pasteurization level takes place. Some bottled beverages call for carbonation to be complete since some virus can not endure carbon dioxide at low temperature levels. https://www.brewbound.com/sponsored/excel-bottling-growing-business-one-bottle-at-a-time/ of drinks will generally require carbonation or a few other approach of pasteurization, such as warm or cold and even a blend of both, in order to be pasteurized.

Most of the bottles in which Batch pasteurizers are packaged today are convection boxes. This sort of box is extremely similar to conveyor belts plus a container that is sealed between as well as take a trip up and down the conveyor. The bottles are positioned on the belt or conveyor as well as the cover is kept in location by stress that is built up in the box. The conveyor belt rotates at the proper speed. check this link right here now moves the bottles around at the suitable price as well as in the appropriate instructions to make sure that they end up in their corresponding containers. It can also move the bottles around at various rates based upon the kind of container being relocated.

There are several benefits of using a tunnel pasteurizer in a food service procedure. When a sterilized beverage item is properly pasteurized, all of the biological issue in it will certainly have been eliminated instantaneously by the speed of the conveyor. This will certainly consist of any kind of impurities that could have survived in the product gradually, such as germs or other bacteria. The temperature level at which the product is sterilized additionally kills any kind of residuals of bacteria or other microorganisms that may be in the item. This permits the quick and also efficient handling of a wide array of different kinds of foodstuff. The pasteurization of food products, especially those that are utilized to feed livestock or human beings, can additionally eliminate the demand for included synthetic plant foods and also vitamins to maintain an ideal diet plan.

Another advantage of using Batch pasteurizers is that they can also be made use of to quicken the spoilage price of soft drinks. Pasteurization of soft drinks has been known to quicken the procedure of ruining drinks by as much as 40 percent. Pasteurizing sodas in these containers permits the pasteurization of the liquid, thus getting rid of the need for fabricated vitamins or other included active ingredients to maintain the flavor and also taste of the drink. Pasteurization of sodas makes it much easier for bottling companies to offer their clients with a product that is pasteurized at a high enough temperature to eliminate any type of germs or other microorganisms that may remain in the fluid.

Batch pasteurizing is a very advanced type of pasteurization utilized today in many sorts of food processing plants. These types of devices are also used in meat and also fish production facilities. This pasteurization process is coming to be much more extensively made use of as a way of protecting food for longer periods of time. This sort of preservation is very important for those that generate and keep food for long periods of time because it assists to maintain the high quality of the product high as well as the life span of the product lasting much longer.

Batch pasteurizers are a popular type of sterilized food. This sort of pasteurizer is used to make refined food last much longer and also maintain it more delicious for a longer period of time. They are typically made use of in dining establishments and also fast food companies to expand the life span of prepared food as well as make it taste also better. There are 2 kinds of Tunnel pasteurizers readily available, set and bottle. Generally, food will be pasteurized at one cycle with a batch machine. Bottled pasteurizer systems are not made use of as frequently as the other type however they do still have their benefits.

Set Batch Pasteurizers are developed for large facilities or business that need to refine huge quantities of food per day. The process of making batch sterilized foods resembles the process made use of by internal warmth exchangers other than it has a heatpump rather than a warm exchanger. Set Tunnel pasteurizers have lots of advantages. They offer batch dimension control which allows you to change the amount of food that experiences the system based upon what you need. There are generally 5 cycles with the lengthiest being 2 hours.

"@context": "https://schema.org", "@type": "Organization", "name": "PRO Engineering / Manufacturing Inc", "url": "https://prowm.com/", "logo": "https://prowm.com/wp-content/uploads/2020/12/PRO_logo_NEW_BLK_large.jpg", "contactPoint": "@type": "ContactPoint", "telephone": "414-362-1500", "contactType": "customer service", "areaServed": ["US","PR"], "availableLanguage": "en" , "sameAs": [ "https://www.facebook.com/PartnerWithPRO", "https://twitter.com/daveone1", "https://www.youtube.com/channel/UCizF9v7dVwMEfY1Qu_E4MPg", "https://www.linkedin.com/company/pro-engineering-and-mfg-inc/", "https://soundcloud.com/pro-engineering-milwaukee" ]

Inner Warmth Exchangers are created for restaurants and also food handling plants to accomplish pasteurization of difficult core items like icy fish, hen, and sodas. The system uses tanks of heated water, in addition to a special detergent, to attain pasteurization. An internal warm exchanger will generally have a holding tank as well as a soft water storage tank to keep the proper water temperature. Some devices use both warm exchangers. To get the right temperature level, many makers make use of either electric pumps or gas-based heating units.

Bottled Batch Pasteurizers makes use of a process called carbonation. Carbonation is accomplished by subjecting the drink to high pressure air which compels co2 right into the interior of the bottle where the wanted pasteurization level takes place. Some bottled beverages call for carbonation to be complete since some virus can not endure carbon dioxide at low temperature levels. https://www.brewbound.com/sponsored/excel-bottling-growing-business-one-bottle-at-a-time/ of drinks will generally require carbonation or a few other approach of pasteurization, such as warm or cold and even a blend of both, in order to be pasteurized.

Most of the bottles in which Batch pasteurizers are packaged today are convection boxes. This sort of box is extremely similar to conveyor belts plus a container that is sealed between as well as take a trip up and down the conveyor. The bottles are positioned on the belt or conveyor as well as the cover is kept in location by stress that is built up in the box. The conveyor belt rotates at the proper speed. check this link right here now moves the bottles around at the suitable price as well as in the appropriate instructions to make sure that they end up in their corresponding containers. It can also move the bottles around at various rates based upon the kind of container being relocated.

There are several benefits of using a tunnel pasteurizer in a food service procedure. When a sterilized beverage item is properly pasteurized, all of the biological issue in it will certainly have been eliminated instantaneously by the speed of the conveyor. This will certainly consist of any kind of impurities that could have survived in the product gradually, such as germs or other bacteria. The temperature level at which the product is sterilized additionally kills any kind of residuals of bacteria or other microorganisms that may be in the item. This permits the quick and also efficient handling of a wide array of different kinds of foodstuff. The pasteurization of food products, especially those that are utilized to feed livestock or human beings, can additionally eliminate the demand for included synthetic plant foods and also vitamins to maintain an ideal diet plan.

Another advantage of using Batch pasteurizers is that they can also be made use of to quicken the spoilage price of soft drinks. Pasteurization of soft drinks has been known to quicken the procedure of ruining drinks by as much as 40 percent. Pasteurizing sodas in these containers permits the pasteurization of the liquid, thus getting rid of the need for fabricated vitamins or other included active ingredients to maintain the flavor and also taste of the drink. Pasteurization of sodas makes it much easier for bottling companies to offer their clients with a product that is pasteurized at a high enough temperature to eliminate any type of germs or other microorganisms that may remain in the fluid.

Batch pasteurizing is a very advanced type of pasteurization utilized today in many sorts of food processing plants. These types of devices are also used in meat and also fish production facilities. This pasteurization process is coming to be much more extensively made use of as a way of protecting food for longer periods of time. This sort of preservation is very important for those that generate and keep food for long periods of time because it assists to maintain the high quality of the product high as well as the life span of the product lasting much longer.