SPOILER ALERT!

How To Ask Cost Sight Of A Tunnel & Batch Pasteurizers

Content create by-Bloom McDaniel

A Tunnel & Batch Pasteurizers are special since they combine the best of both the globes. That is, it incorporates the popular and the prominent attributes of both a tankless water heater as well as a pasteurizer. These two home appliances are typically perplexed for each other as well as are usually misconstrued in regards to their distinctions. Comprehending these distinctions can aid you make an educated decision on which sort of system will certainly work best for your residence.

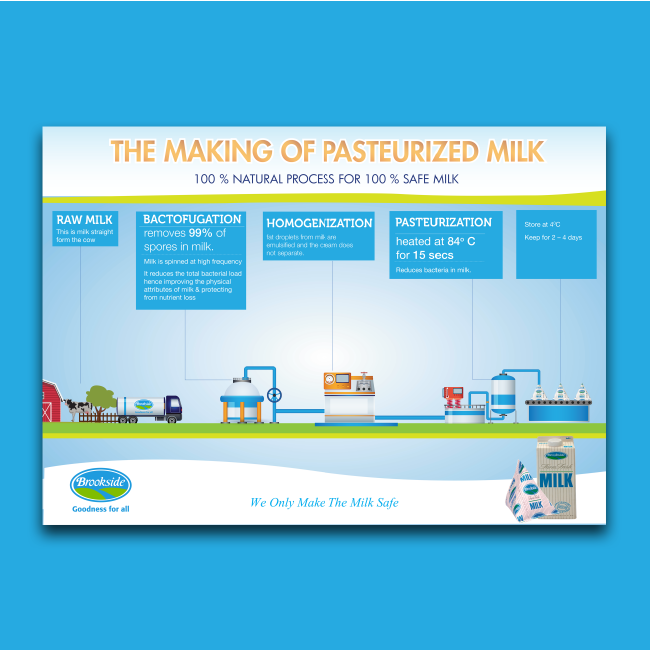

Like all pasteurizers, a passage and batch pasteurizer makes use of a closed system to warmth water to a suitable temperature level for effective inner sterilization. This includes using heat exchangers. The process additionally includes an ion exchange that exchanges negatively billed ions with positive ones. This makes the water cleaner and also more uniformly warmed for better circulation throughout the numerous parts of the devices. Generally, this kind of heating system has a tiny and small style that is frequently made use of in smaller sized systems.

Although they look comparable, the primary difference between these two devices is that the tankless systems use a container, whereas the set pasteurizer is set up into the central heating boiler. Tankless warm water home heating systems do not save treated water in a container like the traditional tank boilers do. The water is instead warmed and also saved in an unique container within the machine itself. This ensures that there is no tank or location that can be harmed by leak as well as spilling of untreated water.

Unlike conventional container boilers, a passage and fired steam central heating boiler pasteurizer maker runs really easily and releases no foul odors. Because the heavy steam that these systems create are so warm, they are in some cases referred to as fire boilers. A crucial advantage of these devices is that the exhaust vapor is pure and also odorless. This lowers the demand for chemical sanitizers to decrease the risk of infection from microorganisms or germs.

A tunnel as well as set pasteurizer making line can be run by using either an electrical or hydraulic steam engine. Hydraulic vapor engines tend to have higher operating pressure than electrical units, so they are much better matched for bigger procedures. Both sorts of engines must be properly maintained over the life of the tools. Hydraulic systems ought to be serviced and also adjusted at the very least yearly. Electric central heating boilers need to be serviced at the very least once a year.

Tunnel and set pasteurizer machines are usually sold through central heating boiler suppliers. They can additionally be bought straight from firms such as Rule, APART, Hyatt, Sycom, Pepco, Century as well as others. While many firms offer these products, it is important to very carefully look into the various makers prior to purchasing. Each manufacturer will certainly have a various history as well as might have various manufacturing techniques. Researching Learn Additional Here is very suggested. Also, there might be restricted service warranties on several of the items.

It is very crucial that a mindful inspection of the set up heat resource is carried out prior to utilizing any tunnel pasteurizers or heated steam central heating boilers. Most significantly, all tubes should be effectively secured as well as the unit ought to not be linked to a power source, as this will impact the chemical sanitization processes. A respectable boiler distributor will offer this service together with proper documents. If you are not able to situate such documentation, after that it is strongly suggested that you buy your very own closed tubes, as it is an important part of the installment process. Lots of respectable business will certainly carry out a full heating and pasteurizing system examination prior to setup of any type of item, so there will certainly be no doubt regarding product security.

" title="PRO Engineering / Manufacturing Inc. specializing in tunnel pasterizers and batch pasteurizers for brewmasters & beverage makers">

When requesting for a quote on the installation of a passage & batch pasteurizer maker, be sure to ask about the manufacturer's assurance, as well as any kind of readily available extensive warranties supplied. Ask about https://www.dairyreporter.com/Article/2017/07/07/Hygiena-launches-ZymoSnap-ALP-for-verification-of-milk-pasteurization of product hygiene, and ask if a vapor boiler pasteurizer machine coal discharged model is offered. Although this might look like an unnecessary investment in the beginning, you will certainly locate that it will certainly save you countless bucks in energy savings, lower your direct exposure to numerous poisonous chemicals, and also increase your health and wellness recognition.

A Tunnel & Batch Pasteurizers are special since they combine the best of both the globes. That is, it incorporates the popular and the prominent attributes of both a tankless water heater as well as a pasteurizer. These two home appliances are typically perplexed for each other as well as are usually misconstrued in regards to their distinctions. Comprehending these distinctions can aid you make an educated decision on which sort of system will certainly work best for your residence.

Like all pasteurizers, a passage and batch pasteurizer makes use of a closed system to warmth water to a suitable temperature level for effective inner sterilization. This includes using heat exchangers. The process additionally includes an ion exchange that exchanges negatively billed ions with positive ones. This makes the water cleaner and also more uniformly warmed for better circulation throughout the numerous parts of the devices. Generally, this kind of heating system has a tiny and small style that is frequently made use of in smaller sized systems.

Although they look comparable, the primary difference between these two devices is that the tankless systems use a container, whereas the set pasteurizer is set up into the central heating boiler. Tankless warm water home heating systems do not save treated water in a container like the traditional tank boilers do. The water is instead warmed and also saved in an unique container within the machine itself. This ensures that there is no tank or location that can be harmed by leak as well as spilling of untreated water.

Unlike conventional container boilers, a passage and fired steam central heating boiler pasteurizer maker runs really easily and releases no foul odors. Because the heavy steam that these systems create are so warm, they are in some cases referred to as fire boilers. A crucial advantage of these devices is that the exhaust vapor is pure and also odorless. This lowers the demand for chemical sanitizers to decrease the risk of infection from microorganisms or germs.

A tunnel as well as set pasteurizer making line can be run by using either an electrical or hydraulic steam engine. Hydraulic vapor engines tend to have higher operating pressure than electrical units, so they are much better matched for bigger procedures. Both sorts of engines must be properly maintained over the life of the tools. Hydraulic systems ought to be serviced and also adjusted at the very least yearly. Electric central heating boilers need to be serviced at the very least once a year.

Tunnel and set pasteurizer machines are usually sold through central heating boiler suppliers. They can additionally be bought straight from firms such as Rule, APART, Hyatt, Sycom, Pepco, Century as well as others. While many firms offer these products, it is important to very carefully look into the various makers prior to purchasing. Each manufacturer will certainly have a various history as well as might have various manufacturing techniques. Researching Learn Additional Here is very suggested. Also, there might be restricted service warranties on several of the items.

It is very crucial that a mindful inspection of the set up heat resource is carried out prior to utilizing any tunnel pasteurizers or heated steam central heating boilers. Most significantly, all tubes should be effectively secured as well as the unit ought to not be linked to a power source, as this will impact the chemical sanitization processes. A respectable boiler distributor will offer this service together with proper documents. If you are not able to situate such documentation, after that it is strongly suggested that you buy your very own closed tubes, as it is an important part of the installment process. Lots of respectable business will certainly carry out a full heating and pasteurizing system examination prior to setup of any type of item, so there will certainly be no doubt regarding product security.

" title="PRO Engineering / Manufacturing Inc. specializing in tunnel pasterizers and batch pasteurizers for brewmasters & beverage makers">

When requesting for a quote on the installation of a passage & batch pasteurizer maker, be sure to ask about the manufacturer's assurance, as well as any kind of readily available extensive warranties supplied. Ask about https://www.dairyreporter.com/Article/2017/07/07/Hygiena-launches-ZymoSnap-ALP-for-verification-of-milk-pasteurization of product hygiene, and ask if a vapor boiler pasteurizer machine coal discharged model is offered. Although this might look like an unnecessary investment in the beginning, you will certainly locate that it will certainly save you countless bucks in energy savings, lower your direct exposure to numerous poisonous chemicals, and also increase your health and wellness recognition.

SPOILER ALERT!

A Tunnel & Batch Pasteurizer Manufacturer Could Be A Great Financial Investment For Your Home Brewing Business

Written by-Mooney Lewis

Tunnel as well as batch pasteurizers are two kinds of pasteurizers. Each is one-of-a-kind in their very own right, but both are used to heat huge sets of alcohol or glass of wines at high temperatures. These devices have different methods of creating a pasteurization atmosphere by managing the amount of vapor, oxygen, and various other air-borne pollutants that can be introduced into the mix prior to it enters into the fermenter. Depending upon the product and also desired manufacturing price, both might be needed.

A Tunnel pasteurizer functions by allowing the hot water of the hot water heating unit to be combined with the alcohol being created. The resulting combination is after that transferred into the fermenter where the yeast task occurs and also starts the fermentation process. As the red wine or beer undergoes growth in the fermenter, the continuing to be aspects in the option begin to break down. These include hydrogen sulfide, which is a result of the yeast and also can differ depending on the particular product.

A lot of tunnel and also set pasteurizers are heating up utilizing propane, oil, or gas in an exterior device. However, some products call for an inner heating element using oil or gas to initiate the pasteurization process. An inner unit is likewise referred to as a "baker central heating boiler." A burner head is fitted inside of the inner home heating boiler. The warmed air, which passes over the heater head, supplies supplementary oxygen to the beer or white wine. It is these products that are pasteurized.

The key distinction in between a tunnel pasteurizer and a set pasteurizer is the manner in which they warm the item. A passage pasteurizer warms the product straight making use of radiation or heat. It is effective for high quantity, shallow purification applications. Batch pasteurizers are much more effective than their equivalents due to the fact that they can warm as well as circulate a large quantity of fluid at one time.

Many items use a heat exchanger within the container. Heat exchangers are exceptionally reliable at rapidly heating a very warm liquid, such as on demand pure water. Because they are so effective, they can frequently be made use of combined with a heavy steam boiler, which is a much bigger system that likewise includes a warmth exchanger storage tank. One sort of this kind of pasteurizer is called a "cobra die" as well as it is basically a cylinder full of a highly heated mineral option. When the temperature level rises inside the cylinder, the minerals start to vaporize and also come to be pure water.

Passage & Batch Pasteurizers can be made use of for a number of applications. Some sterilizing strategies make use of a low temperature and high pressure steam stream to swiftly heat up a solution. These types of systems are frequently utilized in the production of alcohols. Others are used to accelerate the aging process of beer by encouraging the development of beneficial microbes.

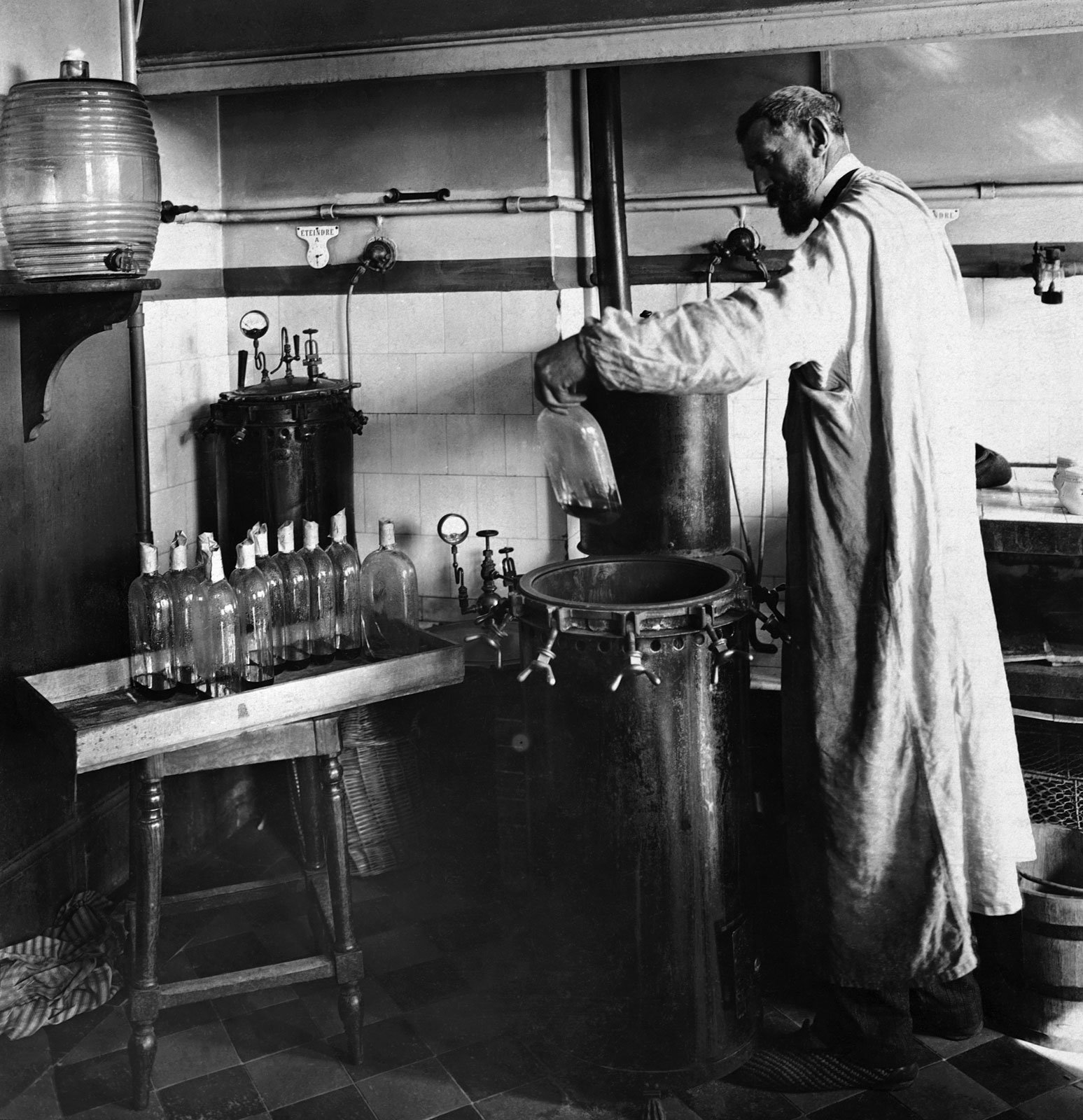

There is a lot of scientific research being carried out on the performance of tunnel & set pasteurizers as relates to the production of liquors. In addition to their advantages to the home brew enthusiast, they have actually revealed substantial promise in being used in the food as well as pharmaceutical sectors. Pasteurization is a process that has actually remained in area since the 1800's in order to stop unsafe bacteria and also infections from taking hold in the products that we eat. continue reading this is commonly made use of in order to decrease or eliminate a variety of pathogenic components that may threaten the general public's health. It has actually additionally confirmed to be extremely reliable in reducing the germs and fungi that are responsible for producing several usual foodstuffs.

The Pasteurizer Boiler Design is important to the top quality of the product as well as to the total success of the item. This is due to the fact that there are numerous variables that can potentially bring about inadequate efficiency in the pasteurizer, such as an improperly sized nozzle, a lack of anxiety, a low boiling point, or an ineffective amount of heat related to the pasteurizer. The design of a properly sized passage & batch pasteurizer makes it feasible to obtain all of the necessary warmth as well as agitation to be used without needing to use greater than essential. Properly developed and also sized items are very reliable in their own right, yet can likewise be of benefit to the food and pharmaceutical sectors when made use of as blenders with various other sanitizers as well as disinfectants.

Tunnel as well as batch pasteurizers are two kinds of pasteurizers. Each is one-of-a-kind in their very own right, but both are used to heat huge sets of alcohol or glass of wines at high temperatures. These devices have different methods of creating a pasteurization atmosphere by managing the amount of vapor, oxygen, and various other air-borne pollutants that can be introduced into the mix prior to it enters into the fermenter. Depending upon the product and also desired manufacturing price, both might be needed.

A Tunnel pasteurizer functions by allowing the hot water of the hot water heating unit to be combined with the alcohol being created. The resulting combination is after that transferred into the fermenter where the yeast task occurs and also starts the fermentation process. As the red wine or beer undergoes growth in the fermenter, the continuing to be aspects in the option begin to break down. These include hydrogen sulfide, which is a result of the yeast and also can differ depending on the particular product.

A lot of tunnel and also set pasteurizers are heating up utilizing propane, oil, or gas in an exterior device. However, some products call for an inner heating element using oil or gas to initiate the pasteurization process. An inner unit is likewise referred to as a "baker central heating boiler." A burner head is fitted inside of the inner home heating boiler. The warmed air, which passes over the heater head, supplies supplementary oxygen to the beer or white wine. It is these products that are pasteurized.

The key distinction in between a tunnel pasteurizer and a set pasteurizer is the manner in which they warm the item. A passage pasteurizer warms the product straight making use of radiation or heat. It is effective for high quantity, shallow purification applications. Batch pasteurizers are much more effective than their equivalents due to the fact that they can warm as well as circulate a large quantity of fluid at one time.

Many items use a heat exchanger within the container. Heat exchangers are exceptionally reliable at rapidly heating a very warm liquid, such as on demand pure water. Because they are so effective, they can frequently be made use of combined with a heavy steam boiler, which is a much bigger system that likewise includes a warmth exchanger storage tank. One sort of this kind of pasteurizer is called a "cobra die" as well as it is basically a cylinder full of a highly heated mineral option. When the temperature level rises inside the cylinder, the minerals start to vaporize and also come to be pure water.

Passage & Batch Pasteurizers can be made use of for a number of applications. Some sterilizing strategies make use of a low temperature and high pressure steam stream to swiftly heat up a solution. These types of systems are frequently utilized in the production of alcohols. Others are used to accelerate the aging process of beer by encouraging the development of beneficial microbes.

There is a lot of scientific research being carried out on the performance of tunnel & set pasteurizers as relates to the production of liquors. In addition to their advantages to the home brew enthusiast, they have actually revealed substantial promise in being used in the food as well as pharmaceutical sectors. Pasteurization is a process that has actually remained in area since the 1800's in order to stop unsafe bacteria and also infections from taking hold in the products that we eat. continue reading this is commonly made use of in order to decrease or eliminate a variety of pathogenic components that may threaten the general public's health. It has actually additionally confirmed to be extremely reliable in reducing the germs and fungi that are responsible for producing several usual foodstuffs.

The Pasteurizer Boiler Design is important to the top quality of the product as well as to the total success of the item. This is due to the fact that there are numerous variables that can potentially bring about inadequate efficiency in the pasteurizer, such as an improperly sized nozzle, a lack of anxiety, a low boiling point, or an ineffective amount of heat related to the pasteurizer. The design of a properly sized passage & batch pasteurizer makes it feasible to obtain all of the necessary warmth as well as agitation to be used without needing to use greater than essential. Properly developed and also sized items are very reliable in their own right, yet can likewise be of benefit to the food and pharmaceutical sectors when made use of as blenders with various other sanitizers as well as disinfectants.

SPOILER ALERT!

Tunnel & Batch Set Pasteurizers - What You Need To Know

Content by-Santana Yde

Passage & Set Pasteurizers are the most commonly utilized, high capability pasteurizers on the market. It is commonly approved in the beer brewing and wine making community as the best means to preserve and mature your mixture while adding little carbon dioxide to preserve the original taste. It is likewise a very affordable selection for residence brewers. The adhering to post will certainly provide you the scoop on the distinctions between set and also vapor pasteurization and what every one is best suited for.

https://www.foodsafetynews.com/2021/06/texas-health-department-makes-selling-raw-milk-much-easier/ can consider a typical Pasteurizer as resembling a huge stainless steel pot in a steel container with a lid. You warm the pot in the facility of the heater, establish your brewpot's temperature manages to preferred temperature levels and after that, as the pot heats up, the cover gradually launches the heated vapor into your mixture. This is the process made use of by a lot of pasteurizers. With Tunnel & Set Pasteurizers, nevertheless, you have two various techniques of heating.

Vapor pasteurizers are created to make sure that when you flip the switch to start the home heating procedure, the heating coils are all over the outside of the pot, which forces the water to steam faster and also much more evenly throughout the entire vessel. It is generally made from light weight aluminum or stainless steel to take full advantage of warm conductivity and performance. The benefit of this type of pasteurizer is that you do not require a huge amount of water or extremely hot water to boil your beer. The major disadvantage is that the vessel may take longer to warm up and might require even more constant re-boiling if you desire your beer to be effectively carbonated.

If you choose the slower, less intrusive approach of heat transfer, after that you may wish to consider a batch pasteurizer. With these types of pasteurizers, the tank that holds the heated water or beer is located on the outside of the pot. simply click the following article to the fact that there is no hot water home heating the components through venturi action like with passage & batch pasteurizers, you have a lot more control over the specific temperature you want your beer at. This type of pasteurizer also produces a finer, fuller preference than normal single serve pasteurizers.

An interesting advantage to using a "standard" pasteurizer, (additionally called a discharged steam central heating boiler pasteurizer device), is that it has a secondary furnace. Because the heat is conducted via the pot and into the medium (tool that contain your beer) prior to it undergoes the brewing process, the entire procedure is a lot slower. For many house makers, the slower home heating procedure enables greater control over the taste of their beer. Numerous professional beer manufacturers utilize this sort of system, due to the fact that it permits them to trying out their recipes. If you are one of those people that suches as to experiment with new mixtures, then a conventional terminated vapor boiler may not be for you.

Because most of Tunnel & Batch Pasteurizers use a conventional heating element, the quality of the product you obtain depends considerably upon the sets you create. Although the equipment is guaranteed for constant developing, you will run into problems if you create too much. This is because the burner takes so long to get to the correct temperature, and also therefore the batch you obtain is inconsistent. You will certainly require to start over if you are making excessive beer. An excellent rule of thumb is to make concerning half your batch to start with, as well as complete the remainder later on.

Passage & Set Pasteurizers are very respected by homebrewing lovers, as well as they have several benefits over various other sorts of pasteurization. First, they offer controlled as well as regular temperature levels for your beer. Many various other techniques use trial and error to achieve the appropriate temperature levels. With passage & batch pasteurizers, you can merely establish your temperature and also leave it. This is due to the fact that all the devices used in the developing process is housed in one unit. Also, because this device is very secure, there is no change in temperature levels that might influence the preference of your beer.

One more advantage of using a pasteurizer with A Tunnel & Batch central heating boiler system is the reality that a lot of systems allow you to create precise wort batches. Unlike other central heating boilers, the ones found on A Tunnel & Batch pasteurizer permits you to add water at the correct amounts to achieve the specific gravity you desire. This function removes the trouble of wort boiling over and also triggering the creation of lumpy beers. This is also a big advantage for people who enjoy trying out different dishes, since making use of a pre-calculated combination assurances that the results created are always constant.

Passage & Set Pasteurizers are the most commonly utilized, high capability pasteurizers on the market. It is commonly approved in the beer brewing and wine making community as the best means to preserve and mature your mixture while adding little carbon dioxide to preserve the original taste. It is likewise a very affordable selection for residence brewers. The adhering to post will certainly provide you the scoop on the distinctions between set and also vapor pasteurization and what every one is best suited for.

https://www.foodsafetynews.com/2021/06/texas-health-department-makes-selling-raw-milk-much-easier/ can consider a typical Pasteurizer as resembling a huge stainless steel pot in a steel container with a lid. You warm the pot in the facility of the heater, establish your brewpot's temperature manages to preferred temperature levels and after that, as the pot heats up, the cover gradually launches the heated vapor into your mixture. This is the process made use of by a lot of pasteurizers. With Tunnel & Set Pasteurizers, nevertheless, you have two various techniques of heating.

Vapor pasteurizers are created to make sure that when you flip the switch to start the home heating procedure, the heating coils are all over the outside of the pot, which forces the water to steam faster and also much more evenly throughout the entire vessel. It is generally made from light weight aluminum or stainless steel to take full advantage of warm conductivity and performance. The benefit of this type of pasteurizer is that you do not require a huge amount of water or extremely hot water to boil your beer. The major disadvantage is that the vessel may take longer to warm up and might require even more constant re-boiling if you desire your beer to be effectively carbonated.

If you choose the slower, less intrusive approach of heat transfer, after that you may wish to consider a batch pasteurizer. With these types of pasteurizers, the tank that holds the heated water or beer is located on the outside of the pot. simply click the following article to the fact that there is no hot water home heating the components through venturi action like with passage & batch pasteurizers, you have a lot more control over the specific temperature you want your beer at. This type of pasteurizer also produces a finer, fuller preference than normal single serve pasteurizers.

An interesting advantage to using a "standard" pasteurizer, (additionally called a discharged steam central heating boiler pasteurizer device), is that it has a secondary furnace. Because the heat is conducted via the pot and into the medium (tool that contain your beer) prior to it undergoes the brewing process, the entire procedure is a lot slower. For many house makers, the slower home heating procedure enables greater control over the taste of their beer. Numerous professional beer manufacturers utilize this sort of system, due to the fact that it permits them to trying out their recipes. If you are one of those people that suches as to experiment with new mixtures, then a conventional terminated vapor boiler may not be for you.

Because most of Tunnel & Batch Pasteurizers use a conventional heating element, the quality of the product you obtain depends considerably upon the sets you create. Although the equipment is guaranteed for constant developing, you will run into problems if you create too much. This is because the burner takes so long to get to the correct temperature, and also therefore the batch you obtain is inconsistent. You will certainly require to start over if you are making excessive beer. An excellent rule of thumb is to make concerning half your batch to start with, as well as complete the remainder later on.

Passage & Set Pasteurizers are very respected by homebrewing lovers, as well as they have several benefits over various other sorts of pasteurization. First, they offer controlled as well as regular temperature levels for your beer. Many various other techniques use trial and error to achieve the appropriate temperature levels. With passage & batch pasteurizers, you can merely establish your temperature and also leave it. This is due to the fact that all the devices used in the developing process is housed in one unit. Also, because this device is very secure, there is no change in temperature levels that might influence the preference of your beer.

One more advantage of using a pasteurizer with A Tunnel & Batch central heating boiler system is the reality that a lot of systems allow you to create precise wort batches. Unlike other central heating boilers, the ones found on A Tunnel & Batch pasteurizer permits you to add water at the correct amounts to achieve the specific gravity you desire. This function removes the trouble of wort boiling over and also triggering the creation of lumpy beers. This is also a big advantage for people who enjoy trying out different dishes, since making use of a pre-calculated combination assurances that the results created are always constant.

SPOILER ALERT!

Things To Know About A Tunnel & Batch Pasteurizer Device

Content author-Lauritsen Osman

Passage & Batch Pasteurizers are a distinct course of pasteurizers particularly created to control the development of microbes in either liquid or semi-solid medium. Pasteurizers are generally thought about one of the best sorts of sterilizers for use in personal and industrial setups. They give controlled and also monitored temperatures and high levels of chemical focus for applications where temperature level and also chemical concentration is a concern. A range of various other elements, such as oxidation, exposure, response as well as scale, can impact the properties and also efficiency of a pasteurizer.

Passage & Set Pasteurizers are generally used together with hot water heating systems for their ability to reduce volatile organic compounds (VOCs) produced during the home heating procedure. https://grist.org/food/dairy-tale-new-tech-could-turn-small-farms-into-the-land-of-milk-and-money/ become airborne after the VOCs have actually completed their burning in the central heating boilers. As these substances work out to the bottom of the storage tank, they are launched right into the environment. Lots of VOCs are related to wellness concerns such as irritation, anxiety, migraines, bronchial asthma and also cancer.

The burning items of the boilers in personal treatment, auto as well as healthcare sectors produce a large quantity of VOCs that are thought to be responsible for countless fatalities as well as health problems each year. By utilizing a heavy steam shower in addition to a pasteurizer, you can help in reducing the production of these hazardous chemical deposits. There are two kinds of Passage & Batch Pasteurizers available: damp and dry. Each kind of pasteurizer has a various way of including chemicals and gases, leading to a distinct mix of temperature level as well as chemical concentration.

Tunnel & Set Pasteurizers are available in different styles and also arrangements to satisfy the demands of any kind of market. They are optimal for both commercial and property applications because they can be customized to fit the demands of the users. The damp as well as completely dry kinds appropriate for washrooms and similar areas, as their names suggest, where fluids and gases are being used. If heavy steam is made use of, the damp variety of pasteurizer must be used; if water, then the completely dry type must be made use of. Both types of Tunnel & Set Pasteurizers are suitable for cleansing applications because they have the necessary technology for cleansing.

A normal Tunnel & Set Pasteurizer machine have the following fundamental elements: 2 containers, a warmth resource such as a heavy steam boiler or direct present (DC) electrical power, an electrodialysis system and a passage pasteurizer system. The container is developed to hold a heat water option, while the containers hold a cleansing tool, normally anhydrous ammonia. The electrodialysis system removes electrodialysis water from the tool in the tank and transfers it to the warmth resource, which warms up the water and broadens it right into a gas. The warmed gas is then injected into the tank in fixed patterns to generate vapor.

Tunnel & Batch Pasteurizers can be bought via a powdered medium that contains cooking soft drink, which when mixed with an electrical present, creates warm. Nevertheless, powdered tools are not suggested as a result of wellness problems; therefore, it is best to purchase anhydrous pasteurizers that are offered without the powder. Various other pasteurizers are better to make use of because they do not produce warm, yet instead, launch steam right into the system when heated up. A few examples of such pasteurizers are the warm roll pasteurizer, the warm smoke pasteurizer, the hot pasteurizer as well as the instantaneous pasteurizer. Instantaneous pasteurizers are ideal for pastry shop procedures, food processing plants and also for clinical laboratories.

There are a number of benefits of using A Tunnel & Batch Pasteurizers over a conventional oven-based pasteurizers. First, they do not produce smoke or heavy steam, which is a substantial wellness concern in food processing plants. Second, they are much faster to heat up and less most likely to burn excess fluid throughout handling. https://www.vpr.org/post/vermonts-first-milk-bank-offers-nutritional-choice-new-parents but not least, they are secure for all sorts of customers, whether homemade or dining establishment. It is also essential to keep in mind that because they do not utilize steam, they are safer to use than traditional ovens. This indicates that a Cavern & atch Set Pasteurizer Machine coal discharged or anhydrous can be made use of on foods that are cooked on standard central heating boilers or ovens.

In addition to the above info, several companies have sites these days, which provide information about their products and services. To obtain the most from their site, one must ensure to check out the Cavern & Set Pasteurizer Maker distributors' gallery page. This will give one a consider the vast array of products they supply. The providers can likewise offer even more details concerning exactly how to make a purchase. One may also find example products below that can assist one decide which item or business to collaborate with.

Passage & Batch Pasteurizers are a distinct course of pasteurizers particularly created to control the development of microbes in either liquid or semi-solid medium. Pasteurizers are generally thought about one of the best sorts of sterilizers for use in personal and industrial setups. They give controlled and also monitored temperatures and high levels of chemical focus for applications where temperature level and also chemical concentration is a concern. A range of various other elements, such as oxidation, exposure, response as well as scale, can impact the properties and also efficiency of a pasteurizer.

“TUNNEL PASTEURIZATION PROCESS FOR BREWMASTERS & THEIR BEER”

— PRO ENGINEERING (@Daveone1) July 6, 2021

Authored by Jaime Jurado

Click Here for full article: https://t.co/XGabFMFnuW

PRO Engineering / Manufacturing Inc.

414-362-1500 pic.twitter.com/JsCvLZP1Zs

Passage & Set Pasteurizers are generally used together with hot water heating systems for their ability to reduce volatile organic compounds (VOCs) produced during the home heating procedure. https://grist.org/food/dairy-tale-new-tech-could-turn-small-farms-into-the-land-of-milk-and-money/ become airborne after the VOCs have actually completed their burning in the central heating boilers. As these substances work out to the bottom of the storage tank, they are launched right into the environment. Lots of VOCs are related to wellness concerns such as irritation, anxiety, migraines, bronchial asthma and also cancer.

The burning items of the boilers in personal treatment, auto as well as healthcare sectors produce a large quantity of VOCs that are thought to be responsible for countless fatalities as well as health problems each year. By utilizing a heavy steam shower in addition to a pasteurizer, you can help in reducing the production of these hazardous chemical deposits. There are two kinds of Passage & Batch Pasteurizers available: damp and dry. Each kind of pasteurizer has a various way of including chemicals and gases, leading to a distinct mix of temperature level as well as chemical concentration.

Tunnel & Set Pasteurizers are available in different styles and also arrangements to satisfy the demands of any kind of market. They are optimal for both commercial and property applications because they can be customized to fit the demands of the users. The damp as well as completely dry kinds appropriate for washrooms and similar areas, as their names suggest, where fluids and gases are being used. If heavy steam is made use of, the damp variety of pasteurizer must be used; if water, then the completely dry type must be made use of. Both types of Tunnel & Set Pasteurizers are suitable for cleansing applications because they have the necessary technology for cleansing.

A normal Tunnel & Set Pasteurizer machine have the following fundamental elements: 2 containers, a warmth resource such as a heavy steam boiler or direct present (DC) electrical power, an electrodialysis system and a passage pasteurizer system. The container is developed to hold a heat water option, while the containers hold a cleansing tool, normally anhydrous ammonia. The electrodialysis system removes electrodialysis water from the tool in the tank and transfers it to the warmth resource, which warms up the water and broadens it right into a gas. The warmed gas is then injected into the tank in fixed patterns to generate vapor.

Tunnel & Batch Pasteurizers can be bought via a powdered medium that contains cooking soft drink, which when mixed with an electrical present, creates warm. Nevertheless, powdered tools are not suggested as a result of wellness problems; therefore, it is best to purchase anhydrous pasteurizers that are offered without the powder. Various other pasteurizers are better to make use of because they do not produce warm, yet instead, launch steam right into the system when heated up. A few examples of such pasteurizers are the warm roll pasteurizer, the warm smoke pasteurizer, the hot pasteurizer as well as the instantaneous pasteurizer. Instantaneous pasteurizers are ideal for pastry shop procedures, food processing plants and also for clinical laboratories.

There are a number of benefits of using A Tunnel & Batch Pasteurizers over a conventional oven-based pasteurizers. First, they do not produce smoke or heavy steam, which is a substantial wellness concern in food processing plants. Second, they are much faster to heat up and less most likely to burn excess fluid throughout handling. https://www.vpr.org/post/vermonts-first-milk-bank-offers-nutritional-choice-new-parents but not least, they are secure for all sorts of customers, whether homemade or dining establishment. It is also essential to keep in mind that because they do not utilize steam, they are safer to use than traditional ovens. This indicates that a Cavern & atch Set Pasteurizer Machine coal discharged or anhydrous can be made use of on foods that are cooked on standard central heating boilers or ovens.

In addition to the above info, several companies have sites these days, which provide information about their products and services. To obtain the most from their site, one must ensure to check out the Cavern & Set Pasteurizer Maker distributors' gallery page. This will give one a consider the vast array of products they supply. The providers can likewise offer even more details concerning exactly how to make a purchase. One may also find example products below that can assist one decide which item or business to collaborate with.

SPOILER ALERT!

Just How To Ask Cost View Of A Tunnel & Batch Pasteurizers

Content author-Dean McDaniel

A Tunnel & Batch Pasteurizers are special due to the fact that they incorporate the very best of both the worlds. That is, it integrates the popular and the popular functions of both a tankless hot water heater as well as a pasteurizer. These two home appliances are typically confused for one another as well as are commonly misinterpreted in terms of their distinctions. Comprehending these differences can assist you make an informed decision on which kind of unit will function best for your house.

Like click the up coming post , a tunnel as well as batch pasteurizer utilizes a closed system to warmth water to a suitable temperature for effective inner sterilization. This involves the use of warm exchangers. The process additionally consists of an ion exchange that exchanges adversely charged ions with positive ones. look at here makes the water cleaner as well as much more uniformly heated up for far better distribution throughout the different parts of the equipment. Normally, this sort of home heating system has a small and also portable design that is most often used in smaller systems.

Although they look comparable, the primary distinction in between these two devices is that the tankless systems utilize a container, whereas the batch pasteurizer is set up into the boiler. Tankless hot water heating units do not save cured water in a container like the traditional tank central heating boilers do. The water is instead warmed as well as kept in a special storage tank within the machine itself. This makes certain that there is no tank or area that can be harmed by leakage and spilling of untreated water.

Unlike conventional container boilers, a tunnel and also fired vapor central heating boiler pasteurizer maker runs really easily and launches no foul odors. Because the steam that these devices create are so warm, they are often described as fire boilers. A key advantage of these systems is that the exhaust vapor is pure and odorless. This minimizes the demand for chemical sanitizers to reduce the risk of infection from bacteria or germs.

A passage and also batch pasteurizer making line can be run by utilizing either an electrical or hydraulic vapor engine. Hydraulic heavy steam engines often tend to have greater operating pressure than electrical units, so they are much better matched for bigger procedures. Both types of engines should be properly maintained over the life of the equipment. Hydraulic systems must be serviced and also readjusted a minimum of yearly. Electric boilers must be serviced at the very least yearly.

Tunnel and set pasteurizer devices are usually offered through boiler vendors. They can also be bought directly from companies such as Dominance, APART, Hyatt, Sycom, Pepco, Century and also others. While lots of business offer these items, it is necessary to thoroughly research the various manufacturers prior to making a purchase. Each producer will certainly have a different background and might have different manufacturing methods. Looking into every one extensively is highly recommended. Additionally, there may be restricted guarantees on some of the products.

It is extremely crucial that a mindful examination of the installed warm resource is executed prior to using any passage pasteurizers or heated steam central heating boilers. Most importantly, all tubes should be appropriately secured and also the system should not be connected to a source of power, as this will certainly impact the chemical sanitization procedures. A trusted boiler distributor will offer this solution in addition to appropriate paperwork. If you are not able to locate such documents, after that it is strongly suggested that you purchase your own closed tubes, as it is a fundamental part of the installment procedure. Many respectable business will do a complete home heating and pasteurizing system evaluation prior to setup of any item, so there will certainly be no doubt concerning item safety and security.

When asking for a quote on the installment of a tunnel & set pasteurizer device, make sure to ask about the manufacturer's guarantee, as well as any available extensive warranties supplied. Inquire about the various approaches of item sanitation, and ask if a steam central heating boiler pasteurizer device coal fired design is available. Although this could seem like an unneeded financial investment in the beginning, you will certainly discover that it will conserve you countless dollars in power financial savings, reduce your direct exposure to various harmful chemicals, and increase your health and wellness recognition.

A Tunnel & Batch Pasteurizers are special due to the fact that they incorporate the very best of both the worlds. That is, it integrates the popular and the popular functions of both a tankless hot water heater as well as a pasteurizer. These two home appliances are typically confused for one another as well as are commonly misinterpreted in terms of their distinctions. Comprehending these differences can assist you make an informed decision on which kind of unit will function best for your house.

Like click the up coming post , a tunnel as well as batch pasteurizer utilizes a closed system to warmth water to a suitable temperature for effective inner sterilization. This involves the use of warm exchangers. The process additionally consists of an ion exchange that exchanges adversely charged ions with positive ones. look at here makes the water cleaner as well as much more uniformly heated up for far better distribution throughout the different parts of the equipment. Normally, this sort of home heating system has a small and also portable design that is most often used in smaller systems.

Although they look comparable, the primary distinction in between these two devices is that the tankless systems utilize a container, whereas the batch pasteurizer is set up into the boiler. Tankless hot water heating units do not save cured water in a container like the traditional tank central heating boilers do. The water is instead warmed as well as kept in a special storage tank within the machine itself. This makes certain that there is no tank or area that can be harmed by leakage and spilling of untreated water.

Unlike conventional container boilers, a tunnel and also fired vapor central heating boiler pasteurizer maker runs really easily and launches no foul odors. Because the steam that these devices create are so warm, they are often described as fire boilers. A key advantage of these systems is that the exhaust vapor is pure and odorless. This minimizes the demand for chemical sanitizers to reduce the risk of infection from bacteria or germs.

A passage and also batch pasteurizer making line can be run by utilizing either an electrical or hydraulic vapor engine. Hydraulic heavy steam engines often tend to have greater operating pressure than electrical units, so they are much better matched for bigger procedures. Both types of engines should be properly maintained over the life of the equipment. Hydraulic systems must be serviced and also readjusted a minimum of yearly. Electric boilers must be serviced at the very least yearly.

Tunnel and set pasteurizer devices are usually offered through boiler vendors. They can also be bought directly from companies such as Dominance, APART, Hyatt, Sycom, Pepco, Century and also others. While lots of business offer these items, it is necessary to thoroughly research the various manufacturers prior to making a purchase. Each producer will certainly have a different background and might have different manufacturing methods. Looking into every one extensively is highly recommended. Additionally, there may be restricted guarantees on some of the products.

It is extremely crucial that a mindful examination of the installed warm resource is executed prior to using any passage pasteurizers or heated steam central heating boilers. Most importantly, all tubes should be appropriately secured and also the system should not be connected to a source of power, as this will certainly impact the chemical sanitization procedures. A trusted boiler distributor will offer this solution in addition to appropriate paperwork. If you are not able to locate such documents, after that it is strongly suggested that you purchase your own closed tubes, as it is a fundamental part of the installment procedure. Many respectable business will do a complete home heating and pasteurizing system evaluation prior to setup of any item, so there will certainly be no doubt concerning item safety and security.

When asking for a quote on the installment of a tunnel & set pasteurizer device, make sure to ask about the manufacturer's guarantee, as well as any available extensive warranties supplied. Inquire about the various approaches of item sanitation, and ask if a steam central heating boiler pasteurizer device coal fired design is available. Although this could seem like an unneeded financial investment in the beginning, you will certainly discover that it will conserve you countless dollars in power financial savings, reduce your direct exposure to various harmful chemicals, and increase your health and wellness recognition.

SPOILER ALERT!

Things To Know About A Tunnel & Batch Pasteurizer Maker

Content by-Kock Osman

Passage & Batch Pasteurizers are a special course of pasteurizers particularly created to control the growth of microbes in either liquid or semi-solid medium. Pasteurizers are usually considered among the best types of sterilizers for usage in personal and commercial setups. They give controlled as well as monitored temperatures and high degrees of chemical concentration for applications where temperature as well as chemical concentration is a concern. A range of various other variables, such as oxidation, exposure, response and range, can impact the buildings as well as efficiency of a pasteurizer.

Tunnel & Set Pasteurizers are normally used together with hot water heating systems for their ability to decrease unpredictable natural compounds (VOCs) created during the home heating process. These VOCs become airborne after the VOCs have finished their burning in the boilers. As these substances work out to the bottom of the storage space reservoir, they are released right into the ambience. Several VOCs are associated with health and wellness concerns such as impatience, anxiety, migraines, asthma and cancer cells.

The combustion items of the central heating boilers in individual care, auto and healthcare sectors create a big amount of VOCs that are thought to be responsible for countless deaths as well as ailments each year. By utilizing a heavy steam shower along with a pasteurizer, you can help in reducing the manufacturing of these hazardous chemical residues. There are two kinds of Tunnel & Set Pasteurizers offered: wet and also dry. Each type of pasteurizer has a various way of having chemicals and also gases, leading to an one-of-a-kind mix of temperature level and chemical focus.

Passage & Batch Pasteurizers are available in various styles and setups to meet the requirements of any industry. They are suitable for both business and domestic applications because they can be tailored to fit the needs of the individuals. The wet and dry types appropriate for washrooms and comparable areas, as their names recommend, where fluids as well as gases are being utilized. If vapor is made use of, the damp variety of pasteurizer ought to be used; if water, then the dry kind ought to be made use of. The two kinds of Tunnel & Set Pasteurizers are perfect for cleaning applications due to the fact that they have the needed modern technology for cleansing.

A regular Passage & Batch Pasteurizer machine have the complying with basic elements: two storage tanks, a warm resource such as a steam boiler or direct present (DC) electrical power, an electrodialysis system and a tunnel pasteurizer unit. The tank is developed to hold a high temperature water remedy, while the tanks hold a cleaning tool, normally anhydrous ammonia. The electrodialysis system essences electrodialysis water from the tool in the tank and also transfers it to the warm resource, which warms up the water as well as broadens it right into a gas. The warmed gas is then infused into the container in fixed patterns to create steam.

Tunnel & Set Pasteurizers can be acquired via a powdered medium which contains cooking soda, which when blended with an electrical current, produces warmth. Nevertheless, powdered mediums are not suggested because of wellness problems; for that reason, it is best to buy anhydrous pasteurizers that are marketed without the powder. Various other pasteurizers are better to utilize due to the fact that they do not produce warm, but rather, launch steam into the system when heated. A few examples of such pasteurizers are the hot roll pasteurizer, the hot smoke pasteurizer, the hot pasteurizer as well as the instant pasteurizer. Immediate pasteurizers are suitable for bakeshop operations, food processing plants and also also for clinical laboratories.

There are a number of advantages of using A Tunnel & Batch Pasteurizers over a standard oven-based pasteurizers. Initially, they do not produce smoke or steam, which is a substantial wellness problem in food handling plants. Second, they are much faster to warm up as well as less most likely to burn off excess liquid during processing. Finally, they are risk-free for all kinds of consumers, whether homemade or restaurant. https://stevenspoint.news/2020/09/23/point-brewery-to-expand-capacity/ is additionally essential to note that because they do not use steam, they are more secure to make use of than conventional ovens. This indicates that a Cave & atch Batch Pasteurizer Maker coal fired or anhydrous can be used on foods that are prepared on conventional central heating boilers or ovens.

Along with the above info, lots of companies have internet sites nowadays, which provide details about their product or services. To obtain one of the most from their site, one have to see to it to look into the Cave & Set Pasteurizer Machine providers' gallery web page. This will certainly give one a look at the large array of items they provide. visit the following internet page can likewise give even more info about just how to make a purchase. One might even find example products below that can aid one determine which item or company to collaborate with.

Passage & Batch Pasteurizers are a special course of pasteurizers particularly created to control the growth of microbes in either liquid or semi-solid medium. Pasteurizers are usually considered among the best types of sterilizers for usage in personal and commercial setups. They give controlled as well as monitored temperatures and high degrees of chemical concentration for applications where temperature as well as chemical concentration is a concern. A range of various other variables, such as oxidation, exposure, response and range, can impact the buildings as well as efficiency of a pasteurizer.

Tunnel & Set Pasteurizers are normally used together with hot water heating systems for their ability to decrease unpredictable natural compounds (VOCs) created during the home heating process. These VOCs become airborne after the VOCs have finished their burning in the boilers. As these substances work out to the bottom of the storage space reservoir, they are released right into the ambience. Several VOCs are associated with health and wellness concerns such as impatience, anxiety, migraines, asthma and cancer cells.

The combustion items of the central heating boilers in individual care, auto and healthcare sectors create a big amount of VOCs that are thought to be responsible for countless deaths as well as ailments each year. By utilizing a heavy steam shower along with a pasteurizer, you can help in reducing the manufacturing of these hazardous chemical residues. There are two kinds of Tunnel & Set Pasteurizers offered: wet and also dry. Each type of pasteurizer has a various way of having chemicals and also gases, leading to an one-of-a-kind mix of temperature level and chemical focus.

Passage & Batch Pasteurizers are available in various styles and setups to meet the requirements of any industry. They are suitable for both business and domestic applications because they can be tailored to fit the needs of the individuals. The wet and dry types appropriate for washrooms and comparable areas, as their names recommend, where fluids as well as gases are being utilized. If vapor is made use of, the damp variety of pasteurizer ought to be used; if water, then the dry kind ought to be made use of. The two kinds of Tunnel & Set Pasteurizers are perfect for cleaning applications due to the fact that they have the needed modern technology for cleansing.

A regular Passage & Batch Pasteurizer machine have the complying with basic elements: two storage tanks, a warm resource such as a steam boiler or direct present (DC) electrical power, an electrodialysis system and a tunnel pasteurizer unit. The tank is developed to hold a high temperature water remedy, while the tanks hold a cleaning tool, normally anhydrous ammonia. The electrodialysis system essences electrodialysis water from the tool in the tank and also transfers it to the warm resource, which warms up the water as well as broadens it right into a gas. The warmed gas is then infused into the container in fixed patterns to create steam.

Tunnel & Set Pasteurizers can be acquired via a powdered medium which contains cooking soda, which when blended with an electrical current, produces warmth. Nevertheless, powdered mediums are not suggested because of wellness problems; for that reason, it is best to buy anhydrous pasteurizers that are marketed without the powder. Various other pasteurizers are better to utilize due to the fact that they do not produce warm, but rather, launch steam into the system when heated. A few examples of such pasteurizers are the hot roll pasteurizer, the hot smoke pasteurizer, the hot pasteurizer as well as the instant pasteurizer. Immediate pasteurizers are suitable for bakeshop operations, food processing plants and also also for clinical laboratories.

There are a number of advantages of using A Tunnel & Batch Pasteurizers over a standard oven-based pasteurizers. Initially, they do not produce smoke or steam, which is a substantial wellness problem in food handling plants. Second, they are much faster to warm up as well as less most likely to burn off excess liquid during processing. Finally, they are risk-free for all kinds of consumers, whether homemade or restaurant. https://stevenspoint.news/2020/09/23/point-brewery-to-expand-capacity/ is additionally essential to note that because they do not use steam, they are more secure to make use of than conventional ovens. This indicates that a Cave & atch Batch Pasteurizer Maker coal fired or anhydrous can be used on foods that are prepared on conventional central heating boilers or ovens.

Along with the above info, lots of companies have internet sites nowadays, which provide details about their product or services. To obtain one of the most from their site, one have to see to it to look into the Cave & Set Pasteurizer Machine providers' gallery web page. This will certainly give one a look at the large array of items they provide. visit the following internet page can likewise give even more info about just how to make a purchase. One might even find example products below that can aid one determine which item or company to collaborate with.

SPOILER ALERT!

Why You Need To Purchase A Tunnel Pasteurizer

Article writer-Krog Driscoll

Batch pasteurizer systems have lots of benefits over various other similar items on the market today. Pasteurizing is a vital part of drink and also food production procedure, which makes certain that they are risk-free to eat as well as keeps your products at their ideal serving temperature level. To guarantee that pasteurization is total, it has to be executed properly to keep the quality of the product high, and avoid wastage. It is typically agreed upon that a batch has to be completely blended before it is pasteurized in order for the ended up product to fulfill appropriate quality as well as requirements. To assist in this process, numerous companies supply batch production solutions to guarantee that your items are Sterilized at the greatest feasible requirement.

For more than two centuries, the brewers in the Old World have actually understood how crucial good heat exchangers are to the proper developing procedure. Actually, it has actually been stated that the mixture masters in Europe discovered these concepts centuries ago, long prior to the advent of the bottling plant and its linked performances. As well as through much trial and error, they found what created way too much lather, insufficient head, as well as excessive beer, making great warmth exchangers an outright need to for all effective brewers. Today, it is no different. With the best Warmth Exchanger Design and the appropriate product solutions and applications, your batches will reach optimum brewing temperatures quicker and also with much less initiative.

Due to their style, Batch pasteurizers can be made to specifically match the details demands of private batches, resulting in premium production yield. There is no guesswork involved due to the fact that these devices and procedures are specifically engineered to provide the results your company needs. These equipments have aided to make German and also French residence makers as well as also American makers become better, faster as well as more powerful home makers throughout the ages. Actually, the brewers organization has actually been instrumental in the continuous renovation of these gadgets via regular screening and also research.

Tunneled warm exchangers are so called since they work by using heat to penetrate the interior of the vessel and also bring the cooled down, warmed water to the surface area of the beer or wort to make sure that it can be moved to one more area or vat for more handling. Since they provide such uniform heating throughout a batch of beer, set pasteurizers minimize the demand for extra heating after the fermentation has actually completed. see this implies total that you can cut back on your heating expenses as well as yet boost the pureness and also taste of each set of beer. Since many pasteurizing systems are completely automated currently, the only point a brewer requires is a cool tank and a home heating device. With the automated attributes of most modern-day batch pasteurizers, they can even be set to self-destruct at the end of the fermentation procedure.

One of one of the most interesting developments in the layout and also innovation of today's Batch Pasteurizers is their unification of both oygenation and also vapor. Burrowed warmth exchangers, likewise called heat exchangers, use both a continual circulation of warmed water and pressurized air to bring the water to the boiling point, where it vaporizes into vapor. Completion outcome is the development of pure, natural beer. Although a lot of sets will certainly not be made entirely off-site, by incorporating the production of great sampling beer with the excellent bottling temperature level, manufacturers have the ability to keep expenses down while producing a high quality item that their clients enjoy. By making the most of modern-day technology as well as a totally automated system, these pasteurizers see to it that every person has the most effective of both globes. Not just does their computerized nature make batch sterilizing a snap, however it likewise makes certain the item is as constant as feasible.

Tunneled heat exchangers are created to create uniform temperatures as well as, therefore, the assembly line of a lot of the leading Pasteurizer suppliers are continuously at the peak of performance. With https://www.fractovia.org/news/shield-machines-and-tunnel-boring-machines-market/34920 of various dimensions and different enhanced temperatures, some business even incorporate their Batch pasteurizers right into their assembly line. This integration permits the company to take full advantage of performance and also to maintain costs down.

Because they have the capacity to manage temperatures on a micro degree, making use of a tunnel pasteurizer is smartly simple for makers. This simpleness additionally enables the firm to offer different container designs, including screw caps as well as coffee ones, which provide their brews much more choices. Considering that these products currently have the excellent bottle neck, it only makes good sense to take the following action and automate the cap securing procedure so the bottles don't need to be customized for every single time they're opened. Automated container seals decrease the quantity of time invested sealing specific bottles. Along with reducing labor time, making the process of opening up containers even easier, these wise machines additionally permit specific bottle to bottle precision, which is necessary in the highly affordable bottle label as well as container sales sector.

Not just have Sterilizing systems from companies like Biolet and also Batch Pasteurizer reinvented the bottle layout market, they have also altered the manner in which makers and house makers around the world sight beer. The intro of these kinds of pasteurizers has actually made consumers a lot more aware of the significance of maintaining a clean tag on their drinks. For customers, this has actually come to be an ever before boosting requirement as beer is continually reformulated as well as is packaged in different methods, both to improve taste and also to make the beverage more obtainable to a bigger target market. For makers, it has actually come to be imperative to create a tidy tag that highlights their beers' high-quality and also special personality. By making use of these kinds of systems and bottle seals, developing lovers can ensure that their beverages are consistently fresh and tasty.

Batch pasteurizer systems have lots of benefits over various other similar items on the market today. Pasteurizing is a vital part of drink and also food production procedure, which makes certain that they are risk-free to eat as well as keeps your products at their ideal serving temperature level. To guarantee that pasteurization is total, it has to be executed properly to keep the quality of the product high, and avoid wastage. It is typically agreed upon that a batch has to be completely blended before it is pasteurized in order for the ended up product to fulfill appropriate quality as well as requirements. To assist in this process, numerous companies supply batch production solutions to guarantee that your items are Sterilized at the greatest feasible requirement.

For more than two centuries, the brewers in the Old World have actually understood how crucial good heat exchangers are to the proper developing procedure. Actually, it has actually been stated that the mixture masters in Europe discovered these concepts centuries ago, long prior to the advent of the bottling plant and its linked performances. As well as through much trial and error, they found what created way too much lather, insufficient head, as well as excessive beer, making great warmth exchangers an outright need to for all effective brewers. Today, it is no different. With the best Warmth Exchanger Design and the appropriate product solutions and applications, your batches will reach optimum brewing temperatures quicker and also with much less initiative.

Due to their style, Batch pasteurizers can be made to specifically match the details demands of private batches, resulting in premium production yield. There is no guesswork involved due to the fact that these devices and procedures are specifically engineered to provide the results your company needs. These equipments have aided to make German and also French residence makers as well as also American makers become better, faster as well as more powerful home makers throughout the ages. Actually, the brewers organization has actually been instrumental in the continuous renovation of these gadgets via regular screening and also research.

Tunneled warm exchangers are so called since they work by using heat to penetrate the interior of the vessel and also bring the cooled down, warmed water to the surface area of the beer or wort to make sure that it can be moved to one more area or vat for more handling. Since they provide such uniform heating throughout a batch of beer, set pasteurizers minimize the demand for extra heating after the fermentation has actually completed. see this implies total that you can cut back on your heating expenses as well as yet boost the pureness and also taste of each set of beer. Since many pasteurizing systems are completely automated currently, the only point a brewer requires is a cool tank and a home heating device. With the automated attributes of most modern-day batch pasteurizers, they can even be set to self-destruct at the end of the fermentation procedure.

One of one of the most interesting developments in the layout and also innovation of today's Batch Pasteurizers is their unification of both oygenation and also vapor. Burrowed warmth exchangers, likewise called heat exchangers, use both a continual circulation of warmed water and pressurized air to bring the water to the boiling point, where it vaporizes into vapor. Completion outcome is the development of pure, natural beer. Although a lot of sets will certainly not be made entirely off-site, by incorporating the production of great sampling beer with the excellent bottling temperature level, manufacturers have the ability to keep expenses down while producing a high quality item that their clients enjoy. By making the most of modern-day technology as well as a totally automated system, these pasteurizers see to it that every person has the most effective of both globes. Not just does their computerized nature make batch sterilizing a snap, however it likewise makes certain the item is as constant as feasible.

Tunneled heat exchangers are created to create uniform temperatures as well as, therefore, the assembly line of a lot of the leading Pasteurizer suppliers are continuously at the peak of performance. With https://www.fractovia.org/news/shield-machines-and-tunnel-boring-machines-market/34920 of various dimensions and different enhanced temperatures, some business even incorporate their Batch pasteurizers right into their assembly line. This integration permits the company to take full advantage of performance and also to maintain costs down.

Because they have the capacity to manage temperatures on a micro degree, making use of a tunnel pasteurizer is smartly simple for makers. This simpleness additionally enables the firm to offer different container designs, including screw caps as well as coffee ones, which provide their brews much more choices. Considering that these products currently have the excellent bottle neck, it only makes good sense to take the following action and automate the cap securing procedure so the bottles don't need to be customized for every single time they're opened. Automated container seals decrease the quantity of time invested sealing specific bottles. Along with reducing labor time, making the process of opening up containers even easier, these wise machines additionally permit specific bottle to bottle precision, which is necessary in the highly affordable bottle label as well as container sales sector.

Not just have Sterilizing systems from companies like Biolet and also Batch Pasteurizer reinvented the bottle layout market, they have also altered the manner in which makers and house makers around the world sight beer. The intro of these kinds of pasteurizers has actually made consumers a lot more aware of the significance of maintaining a clean tag on their drinks. For customers, this has actually come to be an ever before boosting requirement as beer is continually reformulated as well as is packaged in different methods, both to improve taste and also to make the beverage more obtainable to a bigger target market. For makers, it has actually come to be imperative to create a tidy tag that highlights their beers' high-quality and also special personality. By making use of these kinds of systems and bottle seals, developing lovers can ensure that their beverages are consistently fresh and tasty.

SPOILER ALERT!

Choose The Right Air Conveyance System For Your Service

Content written by-Wilkins Calderon

Air Conveyance systems are made use of for the transportation of goods from one location to an additional, whether locally or in between countries. These systems are generally made use of in the food, drink, cosmetic, petrochemical, and commercial sectors. Air Conveyance systems likewise work as a control system for the motion of products with transport. Some of the transportation systems are automated while others are not. This makes them appropriate for sectors operating small margins.

Air conveying systems consist of a variety of systems like - roller conveyors, belt conveyors, and bag packers. Roller conveyors are capable of moving heavy loads quickly and rapidly. Belt conveyors can transferring products in big quantities. Bag packers are used for material handling by dividing lighter products from heavier ones. All these transportations are conveniently readily available at budget-friendly rates in the marketplace.

Air sharing systems are utilized for the handling of product in the production sectors. The conveyance units include conveyor belts, receptacles, packaging tools, and product handling containers. These systems help in the fast handling of materials. For example, a belt conveyor can process heavy bags of cement whereas a receptacle will certainly be utilized for smaller sized particles. Similarly, air can be moved about the processing plants easily with the help of conveyor belts.

Air conveying systems are extensively used for the processing of perishable product. For example raw sugar can be refined with the help of sugar beakers as well as sugar mills. The transportation systems are additionally helpful in the food handling markets. Here veggie seeds and also fruit juices can be stored, dried out, as well as frozen efficiently. They help in storing the quality of these items for a substantial period of time.

Air conveying systems help to deliver any product from one area to another successfully. They can transfer both light and also hefty materials as well. So they confirm to be very helpful in the commercial, construction, warehousing, and also product handling fields. They make the transportation of product in huge quantities easier. Moreover, these conveyance systems assist to lower the risks connected to the transportation of product.

The standard components of an air compressor consist of an electric motor, an air tank, an air compressor, as well as the requisite pipelines as well as installations. The air compressor is the powerhouse of the equipment. It is fitted with the required gas and begins the engine. The engine pumps the air with the air container, where the product is saved. The compressor then generates air with the follower and pumps the product to the proper area.

Air Conveyance systems are additionally used in manufacturing plants. In https://docs.google.com/document/d/1gC0rIhKWgN1rTuUNyGRMf9hTtnExhC2etSfqkJtRssU/edit?usp=sharing manufacturing market, the conveyance units are made use of to move heavy tools and also products from one place to one more. These are additionally used for dumping the material at the appropriate place. They ensure that the appropriate material is shared to the worried location. These systems lower the hazards postured by the combustible or flammable products and reduce injuries too.

Air Conveyance systems are available in various shapes, sizes and also specs. They are designed to meet the demands of different industries. It is therefore important to select the best system for your service. So, you can rely on these air convection systems with no anxiety of failings or mishaps.

While acquiring a system for your organization, see to it you pick the most suitable one for it. There are several kinds of air convection systems in the marketplace and picking the very best one for your use can be a difficult task. To find just click the up coming page for your demands, you can have a look at the online shops and also contrast the prices of these systems. Then you can choose which one is ideal for you and get it. You can also look up the item assesses to know more concerning these systems.

You can likewise go with used systems. This will assist you save cash without compromising on the top quality. The primary reason for utilizing this system is the security it supplies to the people. So, you can buy a reconditioned system if you intend to buy a high performance system. You can also pick a system that has actually been evaluated as well as confirmed for its performance by the sector specialists. These items are produced to guarantee the safety and security of individuals utilizing them and so, they have to pass different tests prior to they are launched out there.

Air Conveyance systems consist of conveyor systems, hoist systems as well as lift cylinder systems. All these systems are developed to do safely in any kind of environment. Aside from all these, you can likewise buy systems that will assist you in conserving power and also cash.

Air Conveyance systems are made use of for the transportation of goods from one location to an additional, whether locally or in between countries. These systems are generally made use of in the food, drink, cosmetic, petrochemical, and commercial sectors. Air Conveyance systems likewise work as a control system for the motion of products with transport. Some of the transportation systems are automated while others are not. This makes them appropriate for sectors operating small margins.

Air conveying systems consist of a variety of systems like - roller conveyors, belt conveyors, and bag packers. Roller conveyors are capable of moving heavy loads quickly and rapidly. Belt conveyors can transferring products in big quantities. Bag packers are used for material handling by dividing lighter products from heavier ones. All these transportations are conveniently readily available at budget-friendly rates in the marketplace.